New Holland Roll-Belt

ROLL-BELT. CHANGE YOUR BALING STYLE.

New Holland has led the Roll-Belt baler segment for over 25 years, and has introduced a string of pioneering firsts that have revolutionised the way variable chamber balers operate today. Over 275,000 Roll-Belt balers are working around the globe in the expert hands of farmers and contractors to bring the harvest home. The latest generation is set to redefine round baling with advanced Roll-Belt technology that can improve capacity by up to 20% and density by up to 5%. What’s more, operators can select between a 150cm or 180cm maximum bale size to suit their individual needs. The Roll-Belt baler will also captivate the eye with its distinctive sweeping lines, which add a touch of class to every baling operation.

Want to know More?

Contact your nearest branch

OUTSTANDING CAPACITY

Think variable chamber productivity. Think New Holland Roll-Belt baler. Capacity has been increased by up to 20% thanks to the redesigned pick-up. Just imagine clearing every field 20% faster, or doing 20% more work every day! This higher throughput means more crop is baled at optimum conditions. The feed assist roller makes all of this possible, funnelling crop into the rotor even more efficiently. Seconds have been shaved off already impressive wrap times to get you back to baling even more quickly.

BALE QUALITY

The Roll-Belt guarantees top drawer bale quality. Always. An all-new moisture sensing system, which uses two discs on either side of the bale chamber to calculate average moisture, enables operators to respond, in real time, to changing baling conditions. Bale shape sensors on either side of the chamber provide instant feedback to the operator so that they can adjust their driving pattern to make perfect shaped bales. Operators can select how dense a core they require. In-cab density adjustment allows the operator to customize the core and outer density of the bales to suit their preference. Softer cores are perfect for easy feeding and when the bale needs to ‘breathe’ whereas a firmer core makes for excellent storage and handling properties. Furthermore, uniform wrapping completes the package.

EASE OF OWNERSHIP

The Roll-Belt baler belongs in the field, and efficient servicing and maintenance means your baler will spend more time in the field, earning its keep, as opposed to being kept. The one piece side and front shields mean operators have unfettered access to all service points and moving parts to keep the baler in tip-top condition. All service points can be reached from the ground and additional net storage enhances baler autonomy.

ABSOLUTE BALING PLEASURE

Operators will relish long baling days as the Roll-Belt baler has been designed with them in mind. IntelliBale™ technology enables the baler to control the tractor’s forward motion: bringing it to a halt when it is ready to wrap the bale, raises and closes the tailgate when the bale has been ejected and then gives a signal to continue baling. Drop floor technology, which can be operated from the cab, together with density control functions, both increase productivity and reduce operator fatigue.

Features

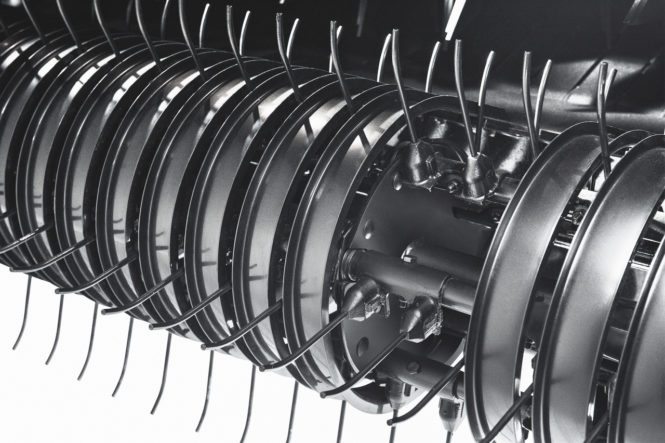

THE FASTEST WAY TO CLEAR FIELDS

The pick-up is perhaps one of the most important parts of your Roll-Belt baler. New Holland has completely redesigned the 2.3 metre wide pick-up to boost capacity by up to 20%. If that wasn’t enough, state-of-the-art baling technology ensures uniform flow for non-stop, high capacity baling.

FLEXIBLE CROP PROCESSING SOLUTIONS

What are your bales going to be used for? As no two baling operations are the same, the Roll-Belt baler offers different crop processing options to suit your individual requirements. The ActiveSweep™ system transfers the crop directly from the pick-up to the bale chamber for gentle handling. The SuperFeed™ option enables straight through processing, to maintain long unbroken straw. CropCutter™ models guarantee super fine chopping for the densest, most nutritious silage bales. No matter what the crop, growing conditions or usage profile, the Roll-Belt baler has an option which is right for you.

FLEXIBLE CROP PROCESSING SOLUTIONS

What are your bales going to be used for? As no two baling operations are the same, the Roll-Belt baler offers different crop processing options to suit your individual requirements. The ActiveSweep™ system transfers the crop directly from the pick-up to the bale chamber for gentle handling. The SuperFeed™ option enables straight through processing, to maintain long unbroken straw. CropCutter™ models guarantee super fine chopping for the densest, most nutritious silage bales. No matter what the crop, growing conditions or usage profile, the Roll-Belt baler has an option which is right for you.

THE PERFECT BALE FOR YOUR OPERATION

New Holland has perfected bale formation and its 275,000 Roll-Belt balers are testament to this success. The combination of both rollers and belts ensures that bales are perfectly formed with a dense core. Furthermore, even density across the entire bale makes them resistant to extensive handling and improves the fermentation profile of silage bales. The variable chamber technology means that operations can vary the size of the bale produced in 5cm increments, from 90cm right up to 150 or 180cm to enhance baling flexibility.

TAILORED WRAPPING OPTIONS

Efficient wrapping is what makes a nice bale, instead of a mountain of material. The entire wrapping system has been upgraded, to speed up the process and to enhance accuracy to deliver best-in-class bale shape first time, every time.

AT A GLANCE BALER MANAGEMENT

The Roll-Belt baler can be specified with a choice of monitors to suit your individual needs, from the entry level Bale Command™ Plus II monitor, or the range topping IntelliView™ III colour touchscreen monitor. You will be able to manage all key baling parameters from the comfort of the cab. The Roll-Belt range features automatic wrapping technology, so when your bale has reached the pre-set size, wrapping automatically begins. If you’ve already got a monitor you like, then the optional ISOBUS compatibility has been designed for you.

FLOATING ACROSS FIELDS, FLYING DOWN ROADS

Specify the ultra-wide 500/55/R20 tyres to increase the in-field footprint to reduce compaction when baling silage, essential to protect valuable shoots and to facilitate regrowth for subsequent cuts. During high speed road transport, these tyres absorb bumps to deliver a smoother, more comfortable ride.

Specifications

New Holland Roll-Belt 150 ActiveSweep™

| Diameter Min. / Max. (cm) | 90 / 150 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / – |

| Feeding system | Overshot feeder / auger |

New Holland Roll-Belt 150 SuperFeed™

| Diameter Min. / Max. (cm) | 90 / 150 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / 2.3 |

| Feeding system | Rotor width 455mm ’W’ tine configuration |

New Holland Roll-Belt 150 CropCutter™

| Diameter Min. / Max. (cm) | 90 / 150 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / 2.3 |

| Feeding system | Rotor width 455mm ’W’ tine configuration |

New Holland Roll-Belt 180 ActiveSweep™

| Diameter Min. / Max. (cm) | 90 / 180 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / – |

| Feeding system | Overshot feeder / auger |

New Holland Roll-Belt 180 SuperFeed™

| Diameter Min. / Max. (cm) | 90 / 180 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / 2.3 |

| Feeding system | Rotor width 455mm ’W’ tine configuration |

New Holland Roll-Belt 180 CropCutter™

| Diameter Min. / Max. (cm) | 90 / 180 |

| Width (cm) | 120 |

| Pick-up working width (m) | 2 / 2.3 |

| Feeding system | Rotor width 455mm ’W’ tine configuration |

Download Brochure

-

Roll-Belt Range

PDF, 3.7 mb Download